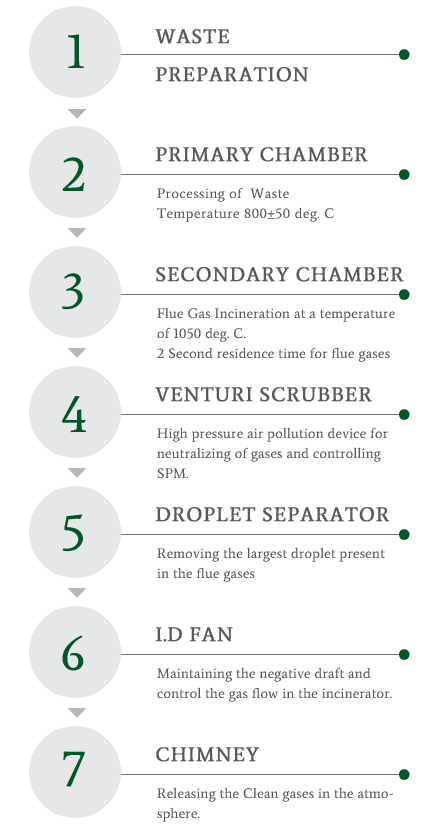

- In the incineration process, the waste is thermally decomposed in the primary chamber at a temperature of 800±50 deg. C. The gaseous products (Volatile mater) are completely oxidized in the(1050±50 deg C.) high turbulence and 100% excess air. The flame port through which the gases pass from primary chamber to secondary chamber is sized to produce high velocity for excellent mixing of combustion air and gases.

- Waste is fed inside the primary chamber of the incinerator through an semi automatic waste feeding system ensuring no direct exposure of the furnace temperature to the operator.

- The incinerator is double chambered and is designed on “controlled air” incineration principle with a minimum of 100% access air. Volatilisation of waste is achieved in primary chamber through supply of air through various nozzles on all sides of the primary chamber, this is done by the F.D fan provided with the incinerator. Heat is generated with fuel oil burner with auto operation system suitable negative draft is maintained in primary chamber to avoid leakage of gaseous emission from it. The sides of the top position of the chambers are rounded up to avoid possibility of formation of dead zones.

- Volatilized/gasified matters from waste are taken to the secondary chamber with residence time 2 second. The heat source in this secondary chamber is auto controlled fuel oil secondary burner. After the gases leave the secondary chamber, they enter the venture scrubber where gases are treated with caustic and scrubbed. A re-circulating pump of stainless steel construction is provided in the system for circulation of caustic and water inside the scrubber. The re-circulation pump is common for the scrubber and droplet separator. All the interconnecting piping is of stainless steel. The gases finally enter the droplet separator wherein the moisture is removed from the gases. This reduces flue gas temperatures making it safe to be let out in the atmosphere. An I.D Fan is provided at the end to release the gases to a 30 mtrs high stack.

- Both the chambers are fitted with burners to fire support for initial heating up of chambers to required temperatures as well as maintain these temperatures.

Services Offered

- Collection, Incineration & Disposal

- Transportation

Facility highlights

- Regularity in Record Keeping

- Green belt area

- Hydrants for fire safety

- Continuous Online emission monitoring

- Hazardous waste Incinerator

- Waste blending and stabilization cell

- Scrubbers for stack emission control

- Rain water harvesting for water conservation

- Fire extinguisher alarms fire safety

- Frequent Medical check-up for Hazardous waste handling employees

- Frequent Safety sessions

Automobile Industry

Chemical Industry

Engineering Industry

Institutes

Packaging Industry

Pharmaceutical Industry

R & D Centers

Amusements Parks